Add to Cart

Product/Mold Description

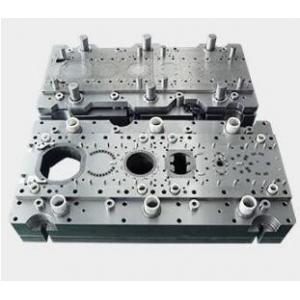

High Progressive Metal Stamping Punching Mold/Die -- Progressive Stamping Die

u In-house mold design and mold manufacturing

u Precision Single-cavity and multi-cavity molds

u Design for Manufacturability

u Fast Turnaround

Properties: OEM DIE

Type: Forming mold

Material: 45#/Cr12MoV/SKD11

Application: Automotive Tier-1 , OEMs

| Product Name | mould | |||

| Material we use | Japan SKD-61, H13 | |||

| Product Weight range | 0.012-12kg | |||

| Biggest product size | 600*600*200mm | |||

|

Product Process Name |

1 | Incoming material inspection | 7 | Cleaning |

| 2 | Material | 8 | Surface treatment | |

| 3 | Die casting | 9 | 100% inspection | |

| 4 | Deburring | 10 | Packaging | |

| 5 | Machining | 11 | Inspecting for delivery | |

| 6 | Tour-inspection | 12 | Delivery | |

| Drawing | Provide by customer, or design according to the sample or custonmer provide your idear . | |||

| Drwing format | Pro/E, AutoCAD, SOLIDWORK,CAD, STP, IGES, etc. | |||

| Mould | Design and produce by ourself | |||

DATA:

| Mould Material | H13,8407 |

| Mould Life Time | 50,000 shots to 10,000,000 |

| Mould Cavity | Single or Multiple |

| Sample Lead Time | 20-45 days |

| Drawing Software Used | UG, PRO-E, SOLIDWORK |

Advantage:

Pre-sale service

1). Reply within 24th hours

2). We offer the engineer consultation to your design for production improvement and cost saving

After-sales service

We expect that our customers will become our long-term partners, based on the premise that we not only provide the technical support, but also because we provide excellent high quality after-sales service as well. We guarantee our quality is same as confirmed sample. If the quality difference with confirmed sample, we will solve the problem to our customer or compensate for it.

Delivery:

1.We will choose different packaging and shipping method according to different die dimensions and quantities.

2.Smaller die be packed in carton boxes and bigger die be packed in ply-wooden boxes, which will provide a strong protect for dies during long-time transportation.

3.To save your time and money, small quantity will be delivered by International Express as your assigned, and large-scale will be delivered by sea.

FAQ:

1. Research and development(R &D):

We have a mature technical team that can assist customers to develop new products and grow together

2. Design:

Free design is available according to the samples or drawings provided by customers

3. Customer service:

Complete customer service support is provided , including logistics, technical services, equipment commissioning etc;

4. Processing:

OEM manufacturing services are provided according to customer’s demand